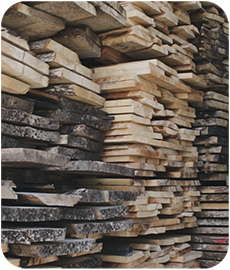

Dozens of years of experience allow us to acquire the best wood available. All of our wood is obtained from sustainable forests, thus not jeopardizing their natural balance.

Wood absorbs moisture. To be properly worked, we dry it in our special greenhouses. Using a hygrometer, it is subsequently checked whether the values are ideal (10% to 14%). This drying dramatically increases the durability and stability of the wood.

Each board is unique. It is necessary to make a pre-selection of the raw material to be used. This is only possible through a thorough inspection to avoid cracks, branches or other imperfections present in the wood.

Machinery precision is crucial. All operations are carried out with utmost attention in order to ensure all final elements are exact copies.

Two presses working simultaneously allow us to bend incredibly diverse shapes. This is done through prefabricated molds made on our CNC machines.

Our 6-axis CNC machines ensure quality in the most delicate jobs. They allow us to cut, mill, and drill the same component always with extremely high precision.

Dozens of specific sanders for each component allow for a homogeneous treatment across the board.

When it comes to the delicate process of assembling the components, there is no better option than the manual work of our experienced employees.

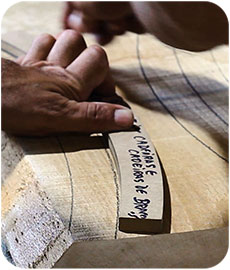

During the production process, the product is properly labeled. This gives us a unique level of traceability.

At this stage, color is applied to the chair. This manual process ensures uniform color distribution to compensate for the different shades of the wood

After applying the color, it is necessary to sand. This entire process is manual, to make sure that the chair reaches its last transformation in perfect condition.

The varnish is applied by a 5-axis robot that guarantees a professional and constant application. Without fatigue and without distractions, the process is completed perfectly.

The chairs are then placed on a giant conveyor belt, where they're guaranteed to dry without any interference.

The upholstery is applied manually by our professionals, who ensure its placement carefully.

Proper packaging is essential. In order to reach our customers in the best possible conditions, the product is packed in a plastic bag, and is protected with cardboard and foam padding.

We are careful to strictly identify all boxes with the respective customer and delivery location. Anywhere in the world is within our reach.